The Pristec Upgrading Process

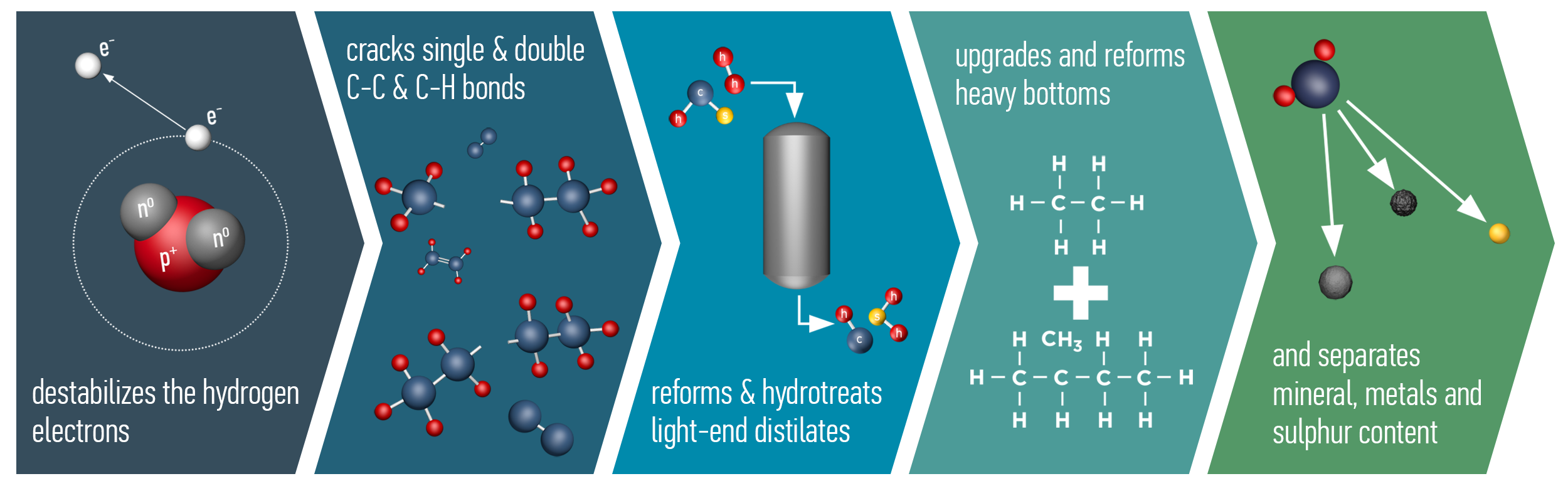

THE PRISTEC COLD CRACKING OIL UPGRADING PROCESS employs acoustic energy at ambient temperatures and atmospheric pressures to significantly reduce dependency on expensive transport and refining processes. This is done by reducing density, sulfur content, specific viscosity and metals while supporting feedstock stability. The resulting distillates are in the diesel and fuel oil ranges, and are relatively low in sulfur and aromatics. The patented, low-maintenance Pristec Cold Cracking units are manufactured by well-known certified industry production partners, and can be quickly installed at various points along the process value chain to start turning immediate profits.

Pristec’s patented technology…

With Pristec as your partner you can…

- significantly reduce the need for diluent at the well head,

- earn more from feedstock,

- upgrade fuel oil directly at the terminal,

- or even upgrade marine fuels while out at sea.

Get in touch with us today to learn more.