VESTA Terminals Project, Tallinn, Estonia

In June 2012 Pristec completed a 6 month industrial Upgrading Process in the Vesta Oil Terminal in Tallinn, Estonia and successfully upgraded Heavy Fuel Oils and other residual products. The results showed “Massive” improvement of all price relevant quality parameters including viscosity and density reduction and increase in API and lights content (proved and certified) through conversion of low value Fuel Oils into high value tradable Fuel Oils.

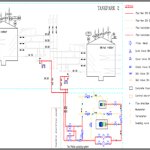

Engineering and Risk Analysis studies led to equipment upgrades suitable for industrial integration of the Pristec system into oil ports and terminals internationally. Further system improvements allow for operation in climates with temperatures as low as minus 20 degrees Fahrenheit.

Pilot testing included tank to tank operation on capacity volumes of 50,000 barrels.

Various heavy fuels and blends were supplied as feedstock and processed at 5000 BPD throughout the 5 month operation.

Much of the treated material was heavy residual (low quality fuel oil) from Russian and Belarus refineries which did not reach international trade specifications.

A one time treatment of Vacuum Gas Oil (VGO) resulted in a 23% increase Gasoil in weight which showed a high profit potential for future upgrading projects in refineries.

A one time treatment of low quality fuel oil resulted in an API increase from 12.88 to 21.14 and a viscosity decrease from 394.8 Cst to 44.15 Cst at 50 degree Celsius which showed the high profit potential for oil terminal operations and upstream.

All quality changes were witnessed and certified by SGS, Intertek and Saybolt.